B Flute vs C Flute Box: Which Corrugated Flute Should You Use?

Jan 16, 2026

B flute vs C flute box: the direct answer

Choose a B flute box when you want a thinner, stiffer board with better crush/puncture resistance and cleaner die-cuts; choose a C flute box when you want more cushioning and better stacking strength for general shipping.

In practical terms: B flute is often the better “space-efficient” choice for mailers, retail-ready packs, and products that need puncture resistance. C flute is the classic all-purpose shipping flute when loads stack in transit or storage and you want more shock absorption.

- B flute: thinner profile, tighter flute count, typically improved puncture/crush resistance and sharper converting.

- C flute: thicker profile, more cushioning, typically improved compression/stacking performance for common shipper cases.

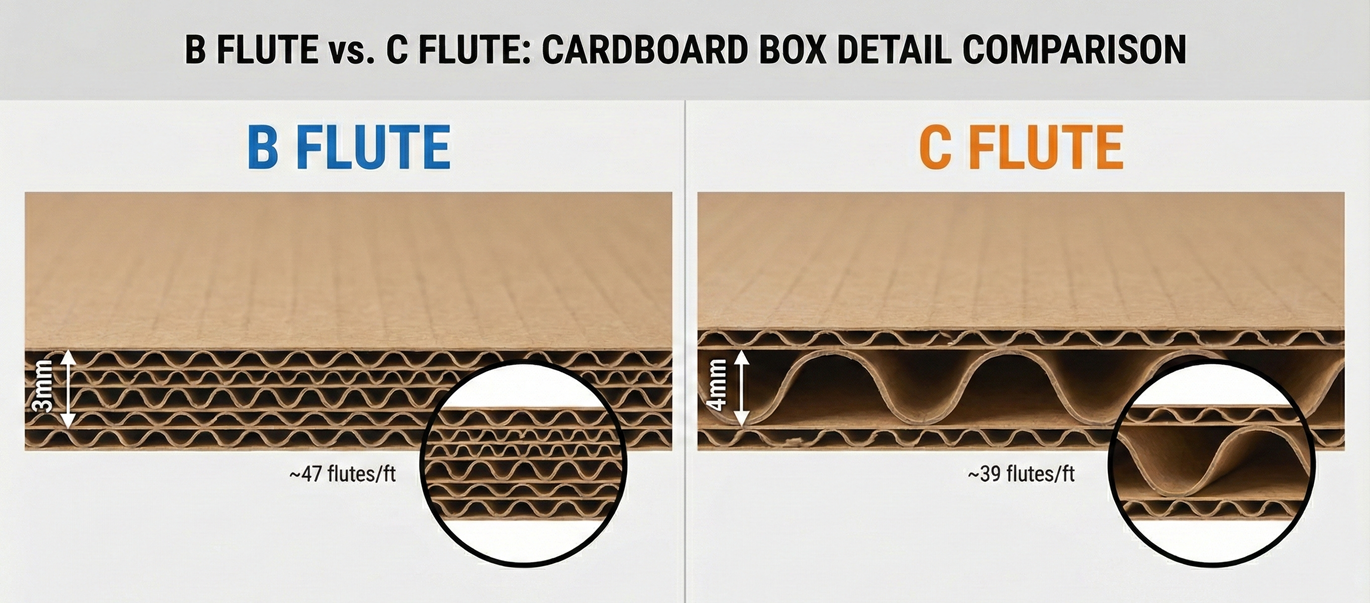

Core specs that explain the difference

Both B flute and C flute refer to the “medium” (the wavy inner paper) profile in corrugated board. The flute geometry changes thickness, stiffness, and how loads distribute through the panel.

| Attribute | B flute | C flute | Why it matters |

|---|---|---|---|

| Nominal thickness | ~1/8 in (≈3.2 mm) | ~3/16 in (≈3.8–4.0 mm) | Thicker boards generally cushion better and can improve stacking for many common case designs. |

| Flutes per linear foot | ~47 | ~39 | More flutes often means a denser structure that can resist crushing and punctures better. |

| Converting & die-cut quality | Typically cleaner creases/cuts | Can be more prone to flute crush if over-scored | Die-cut mailers, tabs, and tight folds tend to benefit from thinner flute geometry. |

| Best-fit use case | Mailers, retail packs, partitions | General shippers, distribution cases | Match flute profile to how your box is handled: drop/shock vs stack load vs puncture risk. |

Important: flute type is only one variable. Liner weights, adhesive, moisture exposure, and the board’s strength rating (ECT or burst) can outweigh flute choice if they differ materially.

Performance trade-offs that matter in real shipments

Stacking and compression (warehouse and pallet loads)

If your boxes are stacked for hours or days (pallet racking, LTL freight, distribution centers), compression performance becomes the critical failure mode. C flute often provides better stacking strength in typical single-wall constructions because the taller flute can help distribute vertical load and add cushioning against panel buckling.

Puncture resistance and edge abuse

If your risk is corner hits, conveyor transfers, or contact with sharp product edges, B flute commonly performs better on puncture and crush-related damage. The denser flute pattern can act like a tighter “ribbed” structure that resists localized intrusion.

Cushioning and vibration

For fragile contents (glass, ceramics, electronics with limited internal cushioning), the extra thickness of C flute can reduce transmitted shock and vibration. This is especially noticeable when internal void fill is minimal and the box itself must contribute to protection.

Printability and scoring quality

When the box is also a “brand surface” (subscription mailers, retail-ready packaging), B flute’s thinner profile typically yields smoother graphics and crisper folds. If you need tight tolerances for inserts, tabs, or self-locking structures, B flute is often easier to convert without flute crush.

Common scenarios: which flute usually wins

Use these as starting points, then validate with your actual board grade and a simple ship test.

Situations that typically favor a B flute box

- Tight dimensional constraints (mailbox fit, subscription kits, inner packs) where an extra ~1/16 in of wall thickness matters.

- Higher puncture exposure: metal parts, sharp corners, frequent conveyor transfers.

- Die-cut structures requiring crisp folds: roll-end trays, self-locking mailers, hang tabs, complex cutouts.

- Retail-ready packaging where print and shelf presentation are important.

Situations that typically favor a C flute box

- General shipping cartons with moderate-to-high stacking during storage or transit.

- Fragile goods that need more wall cushioning when internal packaging is minimal.

- Cases that will see mixed handling conditions (manual + automated) where “all-around” performance is preferred.

- Large panels where added thickness helps resist panel bowing and buckling.

A practical selection checklist (what to measure)

If you need a defensible choice for a B flute vs C flute box, decide based on how your package fails: stack crush, puncture, or drop damage.

- Confirm the board strength rating you’re buying (e.g., ECT or burst) and keep it constant while comparing flute types.

- Estimate stacking load: how many layers on a pallet, and for how long. If stacking is primary, C flute is often the safer baseline.

- Identify puncture risks: sharp product edges, metal components, straps, or frequent conveyor impacts. If puncture is primary, B flute is often favored.

- Check fit constraints: if dimensional weight or mailbox sizing is critical, B flute’s thinner wall can be a material advantage.

- Validate with a simple ship test: a short drop-and-stack trial with your actual pack-out often reveals whether flute choice or internal cushioning is the limiting factor.

Rule of thumb: If you are unsure, start with C flute for standard shippers; move to B flute when you need tighter dimensions, better converting, or improved puncture/crush behavior.

Design tactics that can outperform flute choice

If you are chasing a specific outcome (stacking, puncture, drop), you can often get more improvement by adjusting the box system than by switching only B flute vs C flute.

When stacking is the issue

- Increase board grade (higher ECT) while keeping the same flute type.

- Use a larger manufacturer’s joint and ensure correct box orientation so the strongest panel faces the stack direction.

- Consider double-wall combinations (often BC) if the load truly demands it.

When puncture or abrasion is the issue

- Add pads, partitions, or an inner wrap at contact points rather than changing flute alone.

- Upgrade liner weights or add a protective coating where scuffing and moisture are present.

- Revisit pack-out so product corners are not transferring force directly into the box wall.

When appearance and unboxing quality is the issue

- B flute is often preferred for cleaner printing and sharper folds in mailer-style designs.

- Reduce void space to prevent panel “oil canning” and to improve perceived rigidity.

Cost and logistics implications (with a concrete example)

Material cost varies by supplier and board grade, but flute selection can impact freight, storage, and dimensional constraints.

Space example: If C flute is roughly 1/16 in thicker than B flute, stacking 1,000 flat blanks can add about 62.5 inches (over 5 feet) of bundle height (1,000 × 1/16 in). That can change pallet count, warehouse slotting, and handling efficiency.

- If your shipping program is sensitive to dimensional weight, B flute’s thinner profile can sometimes help keep outer dimensions down.

- If your damage rate is driven by stacking or shock, C flute can reduce total cost by lowering replacement and reship costs—even if the unit cost is slightly higher.

Bottom line

B flute vs C flute box decisions should be driven by your dominant risk: pick B flute for compactness, puncture/crush resilience, and die-cut/print quality; pick C flute for cushioning and typical stacking performance in general shippers.

To make the choice defensible, hold the board grade constant, match flute to the failure mode you see in the field, and confirm with a short ship test using your real pack-out.

English

English  русский

русский  Français

Français  Español

Español  عربى

عربى